Predictive + Preventative maintenance for HVAC and refrigeration equipment

What is preventative maintenance?

Preventative maintenance typically involves a set of tasks that are performed on a regular basis, such as replacing air filters, inspecting and replacing worn or damaged parts, and checking and adjusting equipment settings. These tasks may be performed on a set schedule, such as quarterly or annually.

A lot of small business owners sign up for preventative maintenance contracts with their HVAC and refrigeration contractors. In many cases, building owners write this requirement into leases.

What is predictive maintenance?

Predictive maintenance uses various techniques and technologies to predict when HVAC or refrigeration equipment is likely to fail or require maintenance. The goal of predictive maintenance is to prevent equipment failures and minimize downtime by performing maintenance before problems occur. This can be accomplished through the use of sensors, data analysis, and other technologies that monitor the condition of HVAC and refrigeration equipment and identify potential problems before they occur.

What are the benefits of combining predictive with preventative maintenance?

Preventative maintenance involves performing maintenance on a regular, predetermined schedule regardless of whether it is actually needed. This can be effective at identifying and addressing potential problems before they occur. However, it can also be time-consuming and costly, as maintenance is performed even when it may not be necessary.

Predictive maintenance, on the other hand, involves using data and analysis to predict when maintenance is likely to be needed. This allows maintenance to be performed more efficiently, as maintenance is only performed when it is actually needed. However, predictive maintenance can be more complex since it requires specialized equipment, data analysis software and trained technicians.

By combining preventative and predictive maintenance, businesses can take advantage of the strengths of both approaches. For example, preventative maintenance can be used to regularly inspect and maintain HVAC and refrigeration equipment, while predictive maintenance can be used to identify specific problems and perform targeted maintenance as needed. This can help to optimize the performance of HVAC equipment, reduce downtime, reduce energy use, reduce repair costs and extend the lifespan of the equipment.

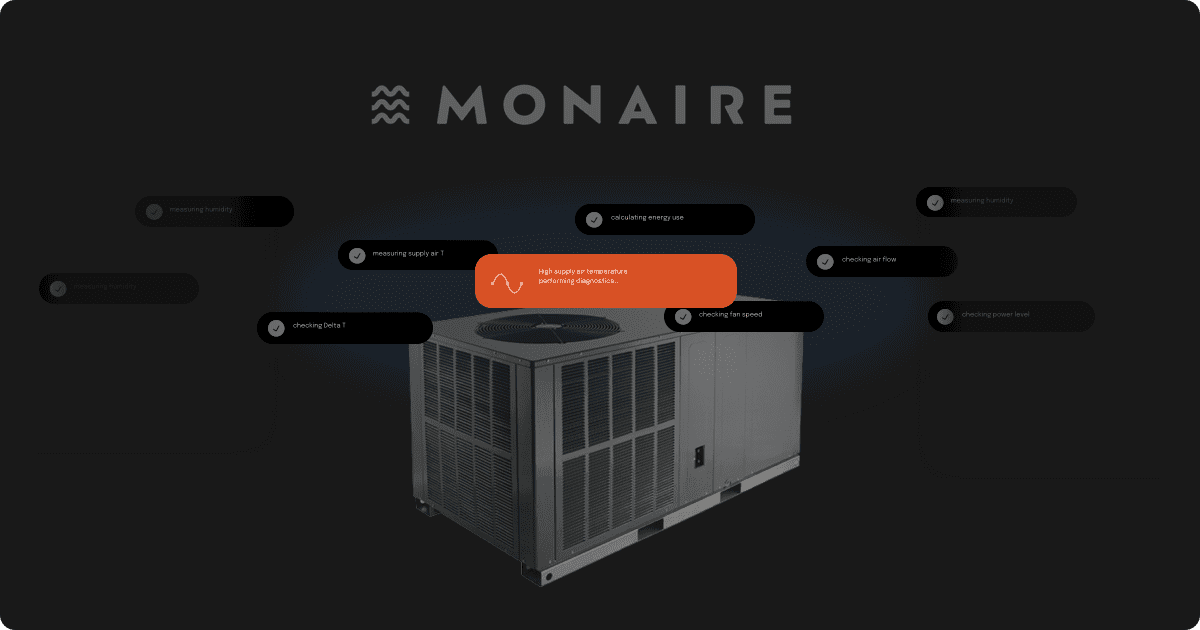

Monaire’s approach to Predictive + Preventative maintenance

Monaire’s unique approach takes advantage of the strengths of both approaches while minimizing weaknesses.

Via preventative maintenance visits, Monaire technicians perform routing maintenance and inspect equipment. Technicians log all their PM visits and use data from previous visits to assess critical aspects about each unit – unlike traditional contractors who may not be performing PM visits and/or may not be logging any data or checking critical points.

Monaire’s continuous predictive monitoring algorithms analyze sensor data and predict when maintenance is needed. Monaire has developed sensors and algorithms that are low cost, easy to install, optimized to work for small buildings and are sold directly by Monaire – unlike products from current HVAC and refrigeration suppliers that are expensive, difficult to install, cater mostly to large buildings and are sold with high markups. Monaire’s technicians are trained to take advantage of the monitoring algorithms data and insights and are able to perform targeted maintenance when needed. Monaire’s algorithms are also able to verify the efficacy of repairs performed by analyzing data before and after the repair was performed.